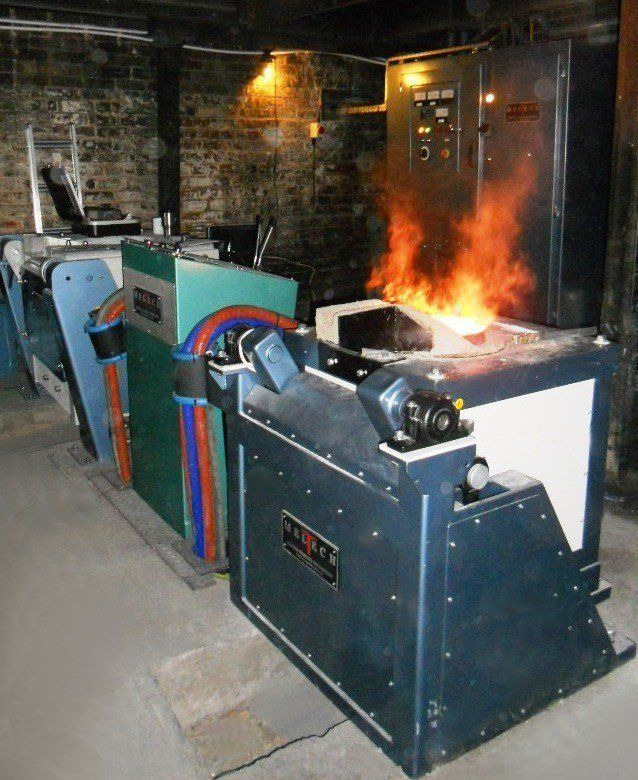

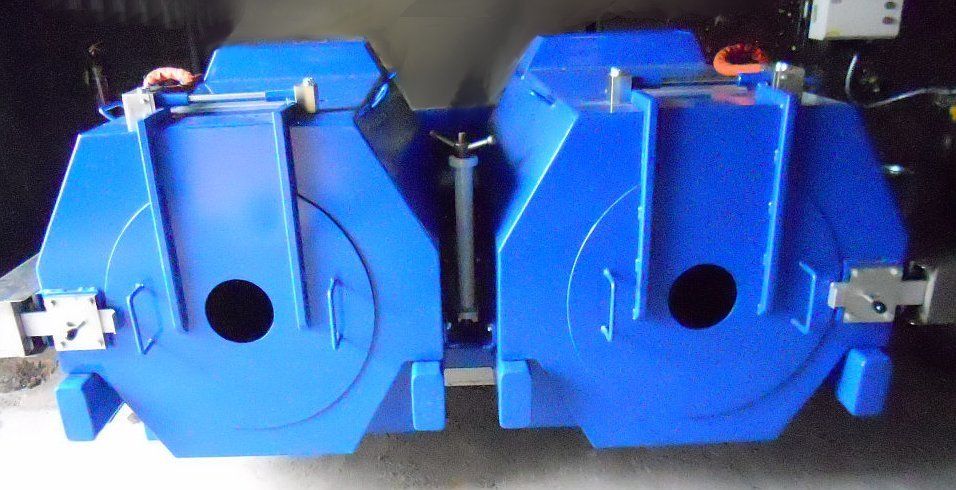

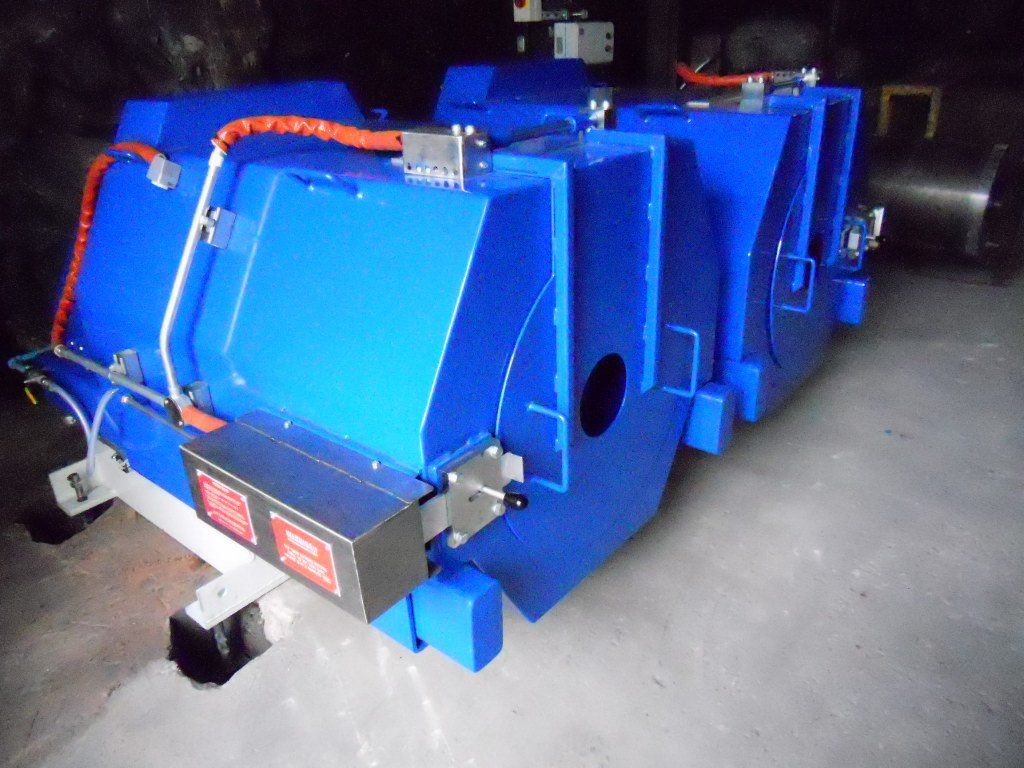

Centrifugal Casting

The centrifugal casting

process in metallic and graphite tooling under high acceleration creates pressure in the alloy which rejects impurities towards and out of the bore which is a preferred method for many phosphor bronze, aluminium

bronze

and brass

grades. This method gives a fine structured alloy that is dense, homogeneous, free from inclusions and blow holes. The mechanical properties are amongst the highest that can be achieved in a casting process. This method of casting is suitable for cylindrical hollows, rings, tubes, flanges and spigot bearings. Castings can be supplied split or segmented if required.

Flanges and spigot bearings can be produced hence saving material and machine costs